侧边栏

article:start

MEMS实验室发表文章

2009年度(9月之后)至2012年度(至9月)

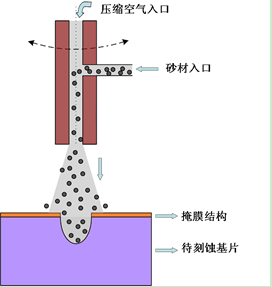

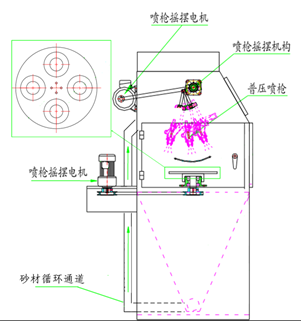

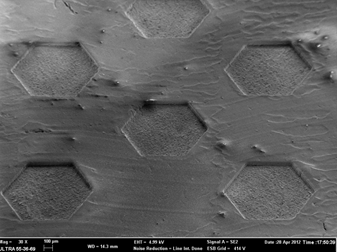

- 一、基于柔性掩膜的高可靠性玻璃喷砂微加工工艺

- 摘要:喷砂是一种高效率的表面整形加工技术,当它与微加工的特殊掩膜技术结合,可以实现对材料表层的选择性刻蚀微加工,即喷砂微加工技术。它对玻璃、硅、陶瓷等脆性材料的微通孔加工尤其有效。其中,掩膜材料及其成型技术是影响微加工性能的决定性因素。本文借助精密切削工艺实现PDMS/SU-8微结构边界精确互补成型,构成了一种高度可重复PDMS掩膜微结构,同时对传统的喷砂清洗机进行改造,使其适应玻璃三维微加工的技术要求。利用上述新工艺对玻璃基片进行喷砂刻蚀加工,并对其中的关键工艺参数影响进行了初步研究。结果表明,喷砂刻蚀具有很高的加工效率,喷砂砂材的颗粒度选择和压缩气压调节均对刻蚀速率具有决定性影响,成型掩膜能够满足500微米玻璃刻蚀通孔的要求。

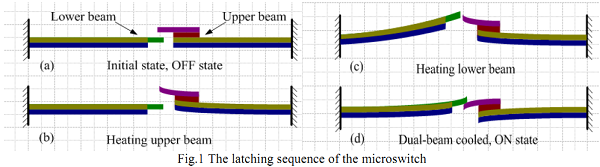

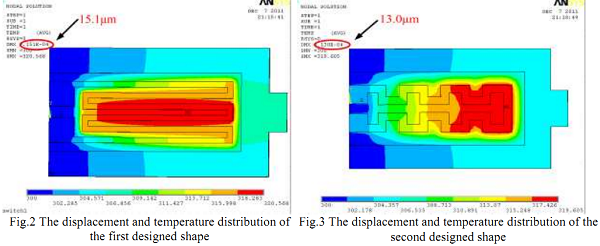

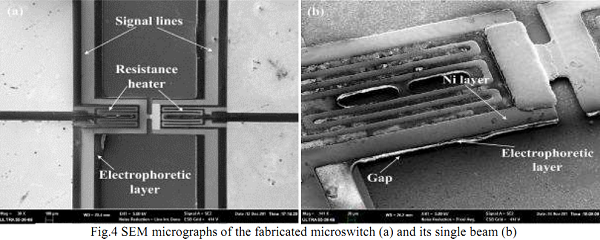

- 二、Design and Characterization of Single Beam for Latching Electrothermal Microswitch

- Abstract. This paper presents the design, fabrication and characterization of single beam for latching electrothermal microswitch. This microswitch consists of two cantilever beams using bimorph electrothermal actuator with mechanical latching for performing low power bistable relay applications. A stable state can be acquired without continuous power which is only needed to switch between two stable states of the microactuator. The single beam is discussed mainly to judge the possibility of realizing the designed function. First, reasonable shape of the resistance is designed using finite element analysis software ANSYS. Then, mechanical performance was characterized by WYKO NT1100 optical profiling system, the tip deflection of single beam can meet the designed demand.

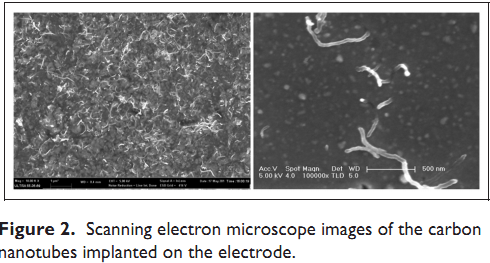

- 三、Electrochemical Reaction of Riboflavin at Carbon-nanotubes/Ni Composite Modified Electrode (CNCME) Fabricated by Composite Electro- deposition of Carbon-nanotubes and Ni Matrix

- Abstract.The paper focuses on the electrochemical behavior of riboflavin (vitamin B2, RF) at carbon-nanotubes(CNTs)/Ni composite modified electrode (CNCME) fabricated by composite electro-deposition of CNTs and Ni matrix. The cyclic voltammetry (CV) is used to compare the electro-catalysis activity of the CNCME and the conventional CNTs modified electrode (CNTME). The CNCME exhibits a marked enhancement of the current response and a reduction of the voltage peak difference. The oxidation-reduction reaction for different PHs and different RF concentrations are discussed. In phosphate buffer solution, there is a good linear relationship between oxidation and reduction peak current and RF concentration in the range from 10-4 to 10-6mol/L with a detection limit of 3.5×10-7mol/L. After fifty CV cycles in RF, the relative standard deviation is only 4.71% for the voltage peak, which indicates that the CNCME has a good reproducible and stable surface.

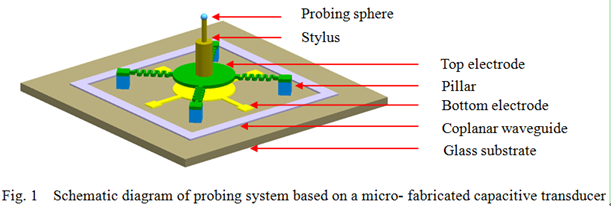

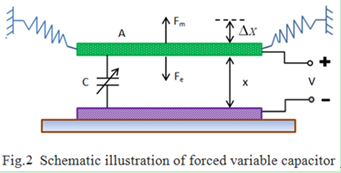

- 四、Design and Fabrication of a Micro-capacitor for Nano Probing System

- Abstract. Quantitative dimensional metrology of Nano- and microstructures are increasingly demanded following the rapid developments in, for instance, semiconductor and precision engineering industry, microsystem technology and materials science. In the recent years, coordinate measuring machines (CMMs) have become versatile and widespread metrology tools. Probing system is an important component of a CMM. A probing system based on a high accurate positioning transducer is crucial for micro and Nano metrology. This paper presents a probing system based on a micro-fabricated variable capacitive transducer which has advantages of simple structure, low cost, high sensitivity, overload ability, excellent dynamic response characteristics, etc. The structure of variable capacitor was designed and optimized by means of finite element method (FEM), and then variable capacitor was micro- fabricated by MEMS technology process.

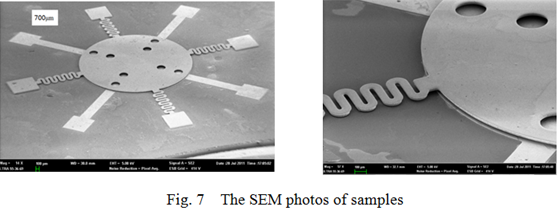

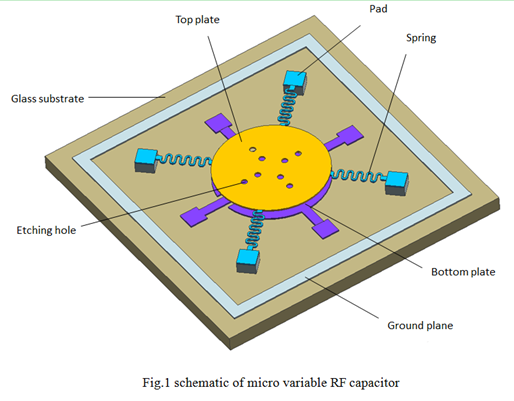

- 五、Micro-machined Variable RF Capacitor Based on Glass Substrate

- Abstract. The RF applications like voltage controlled oscillators, tunable filters, resonators etc., requires variable capacitors in their design. This paper presents a novel micro variable capacitor consisting of fixed plate and moveable plate which is suspended by ‘S’ type springs. Micro variable capacitor can be electrostatically actuated via applied voltage to change the capacitance between the plates. The capacitance changes from15 pF to 22.5pF while applied voltage ranges from 0 to pull-in voltage. And micro variable capacitor based on glass Substrate was fabricated by simple micro electromechanical systems (MEMS) technology.

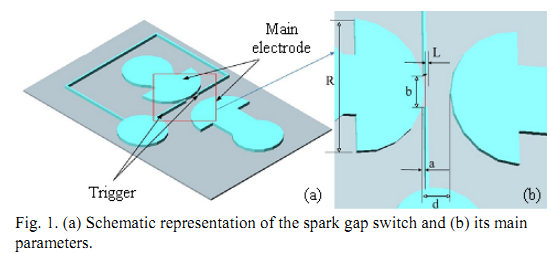

- 六、Design, simulation and characterization of a low-cost in-plane spark gap microswitch with dual-trigger electrode for pulsed power applications

- Abstract.An in-plane spark gap switch with dual-trigger electrode for pulsed power application has been designed and fabricated based on surface micromachining technology. The switch consists of two main electrodes and a dual-trigger electrode to achieve high peak current and smaller trigger voltage. The simulation result shows that 100V trigger voltage could breakdown 30μm distance and then startup the switch. The main discharge channel length has been set as 800μm to get the optimized output of rise time combined with peak current. The prototype microswitch has been fabricated and characterized. The peak and rising edge of the discharge current are 3450.75A and 164ns, respectively, which well agrees with simulation values.

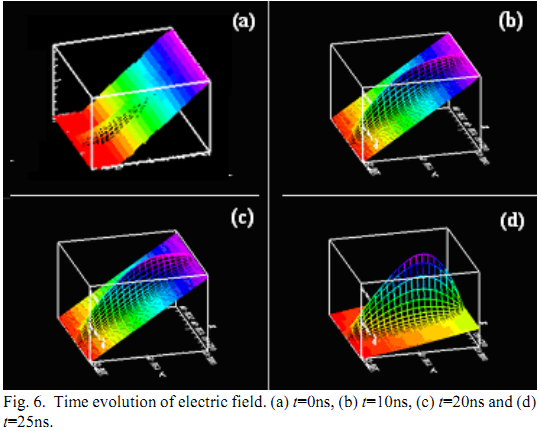

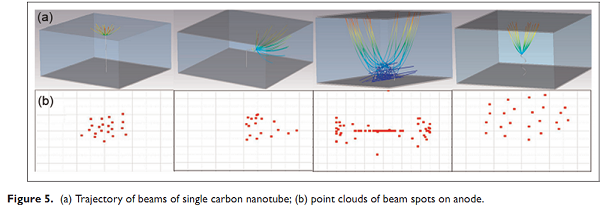

- 七、Numerical analysis in field emission characteristics of carbon nanotube field emitters and arrays

- Abstract.In this study, the field emission characteristics of carbon nanotube field emitters and arrays fabricated by carbon nano-tube implantation process are analyzed by the combination of the finite-difference time-domain and particle-in-cell methods. Carbon nanotubes with different shapes are simulated and their electron trajectory properties are compared. A spacing optimized carbon nanotube field emission array is developed and the impact of random distribution in carbon nanotube length and tilt angle is also investigated. These results are useful to develop an optimized carbon nanotube field emission array that fits current fabrication capabilities.

- 八、不同基底上镍微结构镀层结合强度的研究

- 摘要:在玻璃基底上溅射Ti或Cr/Cu种子层,并对Ti基板表面进行预处理,研究基底表面粗糙度、热处理温度对于镍微结构镀层结合强度的影响。结果表明:基底表面粗糙度、热处理温度对镍微结构镀层与基底的结合强度有较大影响,经过200°C的热处理,溅射Ti及Cr/Cu种子层与镍微结构的结合强度提高近一倍。通过EC-SPM,SEM等分析手段,初步探讨了结合强度的影响机制。

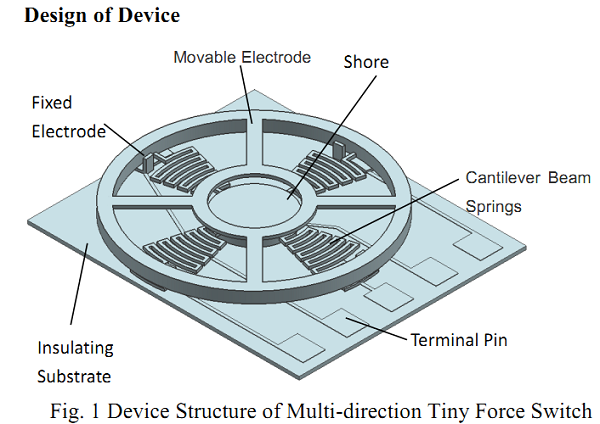

- 九、Designing and Simulation of a Multi-direction Tiny Force Switch

- Abstract. This paper describes the designing and producing of a multi-direction tiny force switch, which is based on the technology of micro-surface processing on privative silicon. The switch is mainly formed by shore, overhanging spring, movable electrode and fixed electrode. Its’ structure material is Ni. The parameters of switch are confirmed by doing finite-element analysis with ANSYS. And rigidities of structure both on horizontal direction and vertical direction are analyzed by using ANSYS to ensure that the uniformity of switch rigidity is qualified. After producing the switch, the rigidity of switch is tested by using bonding tester. The test result shows that the rigidity is almost qualified with requirements.

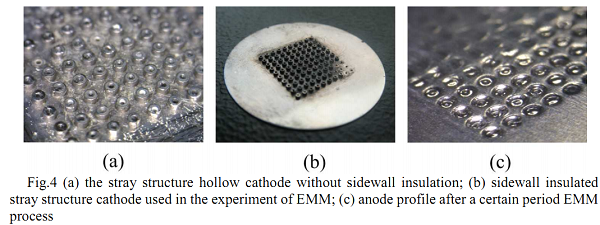

- 十、Research on electrochemical micro-machining in manufacturing engineering by using hollow structure cathode to improve current stability

- Abstract. Since the small inter-electrode gap (IEG), high current density applied, high heat generated and redundant reaction product, the convection of electrolyte in IEG becomes an important factor for the stability of electrochemical micro-machining (EMM) in manufacturing engineering. In this paper, a novel structure of cathode used in EMM is presented. The proper experimental parameters are established from the simulated results. The hollow cathode, which is much more conductive to the flow, has been designed and fabricated on the basis of non-silicon surface micro-machining technology. The experimental test showed the improvement of current stability, and is consistent with the numerical simulations.

- 十一、Study of a novel cathode tool structure for improving heat removal in electrochemical micro-machining

- Abstract. In this paper, the effects of a hollow structure of cathode tool and radial flow of electrolyte on heat removal are studied using COMSOL software. Amulti-physics (electrical field, flowfield and heat transfer) model, which implement the bilateral interactions with customized PDE, is proposed to simulate the EMM process with a moving cathode tool. The ALE method is used to track the moving interface. The simulations show that the electrolyte flow rate and flushing time are the most important factors for the heat removal. A hollow structure of the cathode tool is proposed to improve the stability of flow rate, which will remove the heat generated during the EMM process effectively.

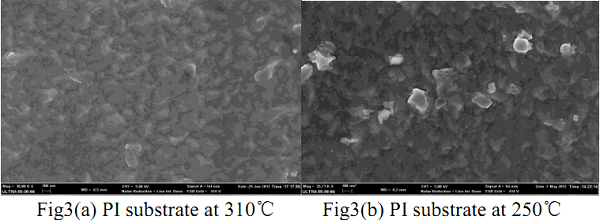

- 十二、Research and Characterization of an Absorber Layer Material—Cu(In,Ga)Se2 Sputtered on Polyimide Substrate in Material Engineering

- Abstract. Cu(In,Ga)Se2 is a very important type of absorber layer material for high efficiency solar cells in material engineering. Cu(In,Ga)Se2 thin films were prepared on polyimide (PI) substrates coated with Mo by RF magnetron sputtering in one-stage at temperature below 450 °C. Samples with high level crystallization were deposited on polyimide coated with Mo by optimizing process parameters. Lower electric resistivity, better quality of CIGS absorber layer was fabricated in lower temperature by sputtering.

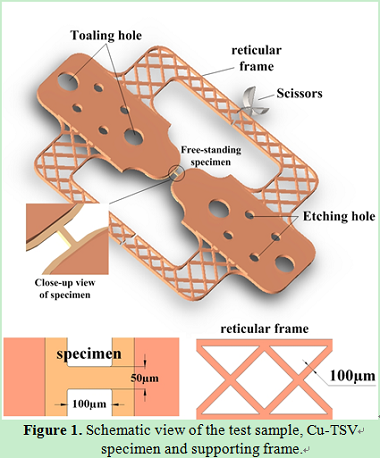

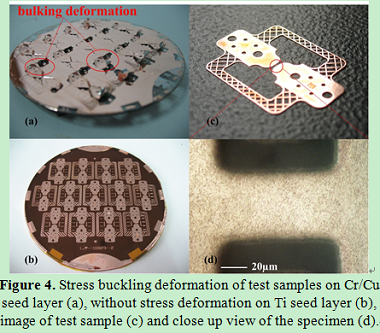

- 十三、Design and Fabrication of Cu-TSV Free-standing Specimen for Uniaxial Micro-tensile Test

- Abstract.A novel test sample with a micro scale free-standing specimen of Cu-TSV used for uniaxial micro-tensile test is presented in this paper. Design of a deformation-buffer reticular supporting frame of the test sample effectively reduces the deformation of Cu-TSV thin film during clamping operation. The stress resulting from electrodepositon process is minimized by fabricating Cu-TSV thin film on surface-treated titanium seed layer. The process of titanium seed layer avoids alkali corrosion and simplifies fabrication procedure compared with that of the traditional Cr/Cu seed layer. Both finite-element method (FEM) simulation and experimental results indicates the advantages of this new design. The test sample fabricated by the optimized process well coordinates with our micro-tensile system. The Young’s modulus and the ultimate tensile strength of tested Cu-TSV thin film measured by our micro-tensile system are 25.4~32.9GPa and 574~764MPa, respectively.

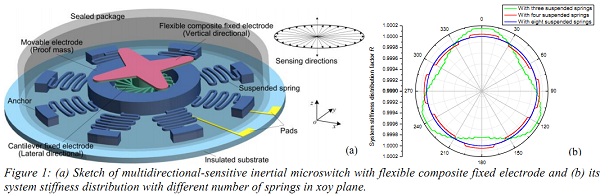

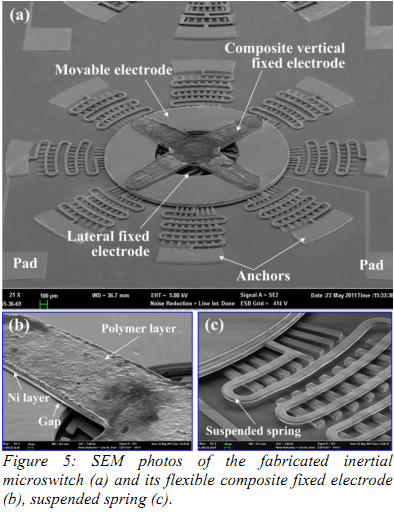

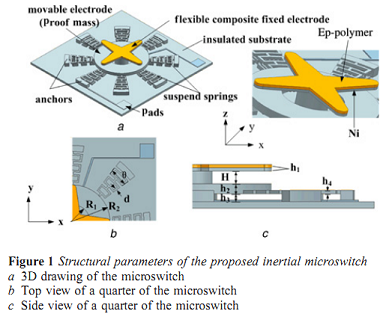

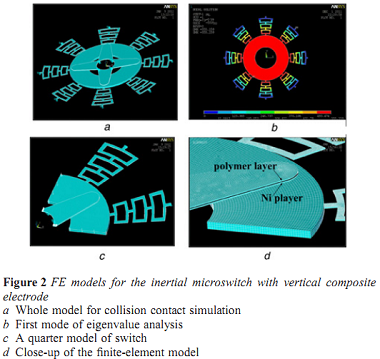

- 十四、A Multidirectional-Sensitive Inertial Microswitch with Electrophoretic Polymer-metal Composite Fixed Electrode for Flexible Contact

- Abstract. A multidirectional-sensitive inertial microswitch with polymer-metal composite fixed electrode has been designed and fabricated based on surface micromachining in the present work. The microswitch can sense the applied accelerations from any directions in xoy plane and positive z-axis. Its vertical composite fixed electrode is completed by electroplating and electrophoretic deposition, which can realize a flexible contact between the electrodes and eliminate the bouncing phenomenon and prolong the contact time. As a result, the stability and reliability of the inertial switch could be greatly improved. The test results show that the threshold acceleration of the fabricated prototype is generally uniform(~70g) in different sensitive directions in x-o-y plane and z-axis. The contact time of the microswitch with composite fixed electrode is ~110µs in vertical direction, which is longer than that (~65µs) of one without polymer.

- 十五、Design and characterisation of an inertial microswitch with electrophoretic polymer–metal composite fixed electrode for extending contact time

- Abstract. Based on non-silicon surface micromachining, a single sensitive direction (z-axis) inertial microswitch with electrophoretic polymer–metal composite fixed electrode has been designed and characterised in the present work. The microswitch mainly consists of two parts: a suspended proof mass as movable electrode and maple leaf-like top as vertical electrode. When an acceleration (threshold level or over) is applied to the switch along its sensitive direction, the mass electrode will rapidly move towards and touch the vertical fixed electrode, switching on the external circuit. The vertical composite fixed electrode of the microswitch can realise a flexible contact, decrease bounce and extend the contact time between the electrodes. The fabricated microswitches have been characterised by a standard dropping test. The threshold acceleration of the prototype is about 70 g while the contact time is about 110 ms, longer than that (about 65 ms) without a polymer.

- 十六、Design and Dynamics simulation of a micromachined inertial switch with polymer-metal composite fixed electrode for flexible contact

- Abstract. A novel inertial micro-switch with polymer-metal composite fixed electrode has been designed based on non-silicon surface micromachining technology. The micro-switch can sense the applied accelerations from positive z-axis. It can realize a flexible contact between the electrodes, eliminate the bouncing phenomenon and prolong the contact time. The dynamic contact simulation of the micro-switch has been implemented under the half-sine wave shock with 80g peak value, and its vertical response time is about ~80µs.

- 十七、Fabrication and characterization of a multidirectional-sensitive contact-enhanced inertial microswitch with a electrophoretic flexible composite fixed electrode

- Abstract. A multidirectional-sensitive inertial microswitch with a polymer–metal composite fixed electrode has been designed and fabricated based on surface micromachining in this work. The microswitch mainly consists of a suspended proof mass as a movable electrode and a T-shaped structure on the substrate with maple leaf-like top and cantilevers around the central cylinder as vertical and lateral fixed electrodes. It can sense the applied shock accelerations from any radial direction in the x-o-y plane and z-axis. The new vertical composite fixed electrode of the switch is completed by electroplating and electrophoretic deposition, which can realize a flexible contact between the electrodes and reduce the bounces and prolong the contact time. As a result, the stability and reliability of the inertial switch could be greatly improved. The fabricated microswitches have been tested and characterized by a standard dropping hammer system. It is shown that the threshold acceleration of the prototype is generally uniform in different sensitive directions in the x-o-y plane and z-axis, which is about 70 g. The contact time of the microswitch with the composite fixed electrode is ∼110 μs in the vertical direction, which is longer than that (∼65 μs) without a polymer. The test data are in agreement with dynamic finite-element simulation results.

- 十八、一种新型三维多方向敏感的非硅微机械惯性开关

- 摘要:基于非硅表面微加工技术,设计并制造了一种新型的三维多方向敏感的微惯性开关。开关选用弹簧-质量块-阻尼的典型碰撞结构,主要由作为可动电极的悬臂梁弹簧—质量块系统、水平固定电极、垂直复合柔性固定电极三部分组成。利用 ANSYS 有限元软件对器件进行了模态和动力学碰撞仿真分析,并对制得的微机械惯性开关进行了落锤冲击试验,结果表明,微开关在水平和竖直方向的阈值水平均为 50~60g,接触时间可稳定在40 s 以上。

2009年度(至2009年9月)

- Analysis and elimination of the 'skip contact' phenomenon in an inertial micro-switch for prolonging its contact time, Yang Zhuoqing, Guifu Ding, Haogang Cai, Xiaoxue Xu, Hong Wang and Xiaolin Zhao, Journal of Micromechanics and Microengineering (accepted)

- Analysis, simulation and fabrication of MEMS spring for micro-tensile system, Rui Liu, Hong Wang, Xueping Li, Jun Tang, Shenping Mao, Guifu Ding, Journal of Micromechanics and Microengineering, vol. 19, no. 1, 015027, 2009.

2008年度

- Numerical analysis of heat transfer in a manifold microchannel heat sink with high efficient copper heat spreader,Wang, Y; Ding, GF MICROSYSTEM TECHNOLOGIES-MICRO-AND NANOSYSTEMS-INFORMATION STORAGE AND PROCESSING SYSTEMS

- A MEMS inertia switch with bridge-type elastic fixed electrode for long duration contact Zhuoqing Yang, Guifu Ding, Haogang Cai, etc., IEEE Transactions on Electron Devices, vol. 55, no. 9, pp. 2492-2497, 2008.

- A micro-tensile method for measuring mechanical properties of MEMS materials, Rui Liu, Hong Wang, Xueping Li, Guifu Ding, Chunshen Yang, Journal of Micromechanics and Microengineering, vol. 18, no. 6, 065002, 2008.

- Experimental investigation of heat transfer performance for a novel microchannel heat sink, Yan Wang, Guifu Ding, Journal of Micromechanics and Microengineering, vol. 18, 035021, 2008.

- Design, simulation and fabrication of anovel contact-enhanced MEMS inertial switch with a movable contact point, Haogang Cai, Guifu Ding, Zhuoqing Yang, Zhijuan Su, Jiansheng Zhou and Hong Wang, Journal of Micromechanics and Microengineering, vol. 18, 115033, 2008.

- Micromechanical characterization of electroplated permalloy films for MEMS, Xueping Li, Guifu Ding, Taeko Ando, Mitsuhiro Shikida and Kazuo Sato, Microsystem Technologies, vol. 14, no. 1, pp. 131–134, 2008.

- Design and simulation of a novel bridge-like coplanar waveguide for microelectromechanical systems, Xiaofeng Sun, Guifu Ding, Hong Wang,Zhenxin Jiang,Binhong Li and Minyi Shen, Microsystem Technologies, vol. 14, no. 1, pp. 95–98, 2008.

- Design and simulation of MEMS-based broadband unidirectional CPW-fed rectangular slot antenna, WeiQiang Chen, GuiFu Din, BinHong Li, Microsystem Technologies, vol. 14, no. 3, pp. 343–347, 2008.

- Fabrication of a MEMS inertia switch on quartz substrate and evaluation of its threshold acceleration, Haogang Cai, Zhuoqing Yang, Guifu Ding, etc., Microelectronics Journal, vol. 39, no. 9, pp. 1112-1119, 2008.

- Packaging of optical fibers using microfabricated nickel clamps, Xuhan Dai etc., Journal of Micro/Nanolithography, MEMS, and MOEMS, vol. 7, no. 1, 010501, 2008.

- Effects of aging on the Characteristics of TiNiPd shape memory alloy thin films, Congchun Zhang etc., Materials Characterization, vol. 59, no. 7, pp.957-960, 2008.

- Preparation of (100)-oriented LaNiO3 for the textured Ba0.5Sr0.5TiO3 thin Films on Si, Congchun Zhang etc. , Applied surface science, vol. 255, pp. 2773-2776, 2008.

2007年度

- Design, simulation and characterization of an inertia micro-switch fabricated by non-silicon surface micromachining, Zhuoqing Yang, Guifu Ding, Weiqiang Chen etc., Journal of Micromechanics and Microengineering, vol. 17, pp.1598-1604, 2007.

- Novel optic-fiber switches based on the wobble-type MEMS electromagnetic microactuator, Shuhai Jia, Guifu Ding, Xiaolin Zhao and Chunsheng Yang, Optics & Laser Technology, vol. 39, pp. 353–358, 2007.

- Preparing Ni-W Alloy Films with Low Internal Stress and High Hardness by Heat Treating, Rui Liu, Hong Wang, Jinyuan Yao, Xueping Li,Guifu Ding, Surface Review and Letters, vol. 14, no. 06, p 1107-1112, 2007.

- Micro-electromechanical systems variable optical attenuator based on nonsilicon surface micromachining technology, Xuhan Dai etc., J. Micro/Nanolithography, MEMS, and MOEMS, vol.6, no. 2, 023010, 2007.

- Design, fabrication and performance of a new vibration-based electromagnetic micro power generator, Peihong Wang, Xuhan Dai, etc., Microelectronics Journal, vol. 38, no. 12, pp. 1175-1180, 2007.

2006年及以前

整理中